Austin Key and Jacob Stephens

Overview

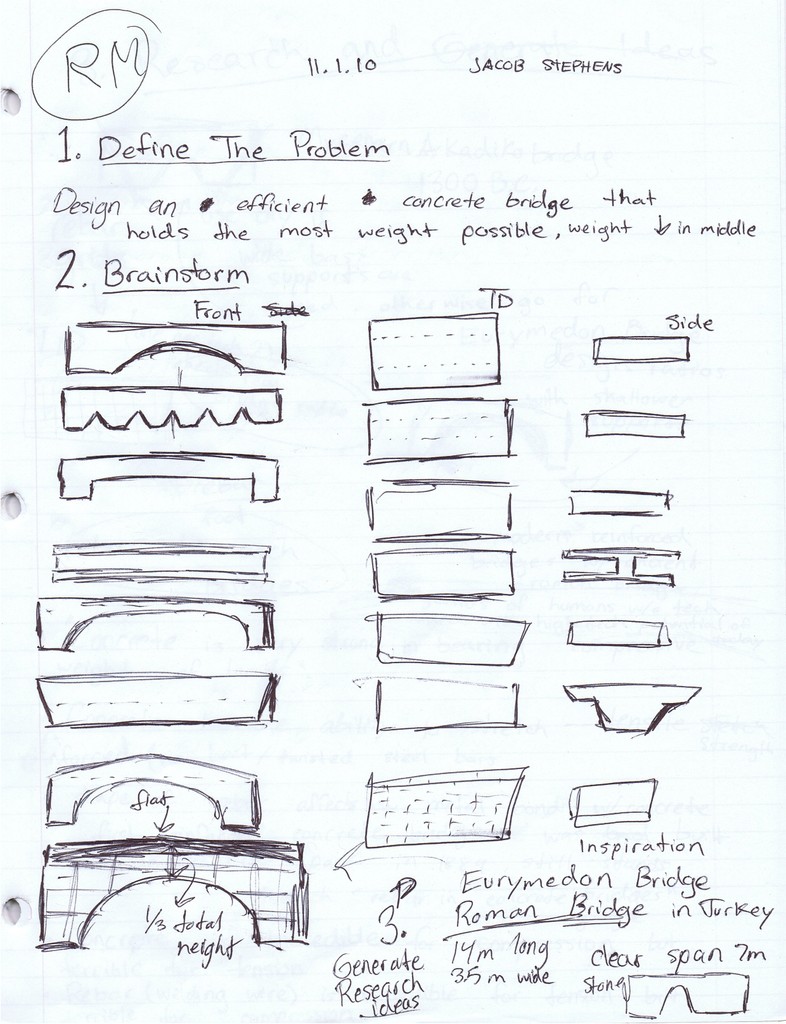

Our goal was to create a

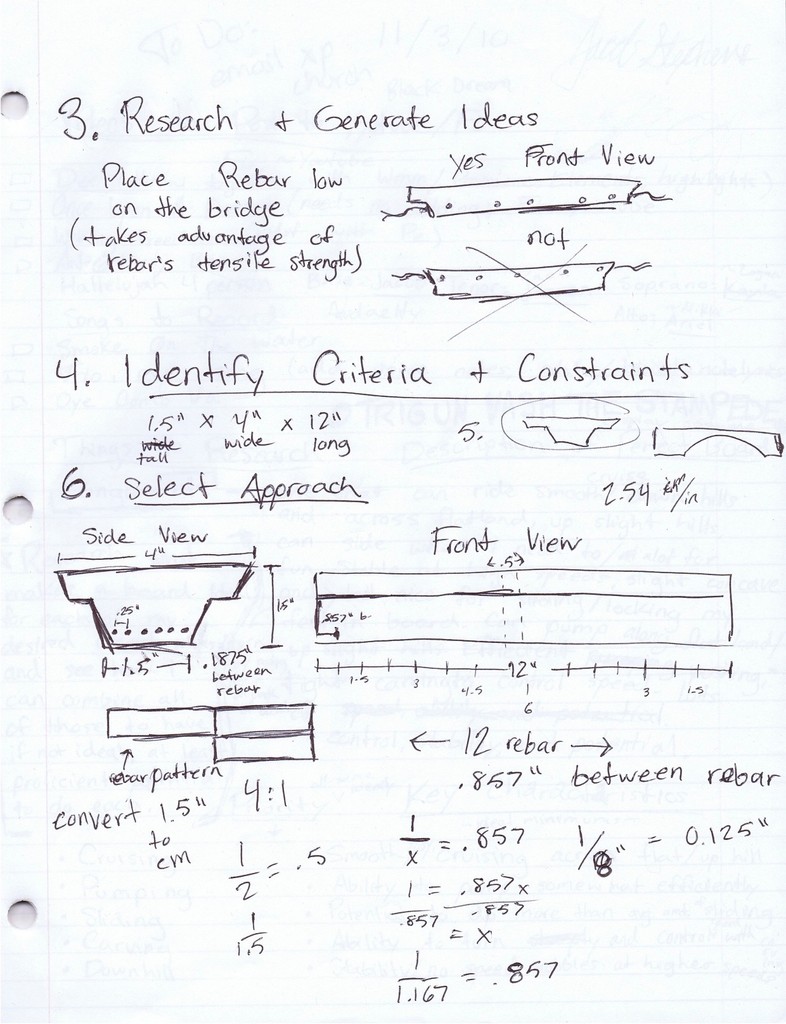

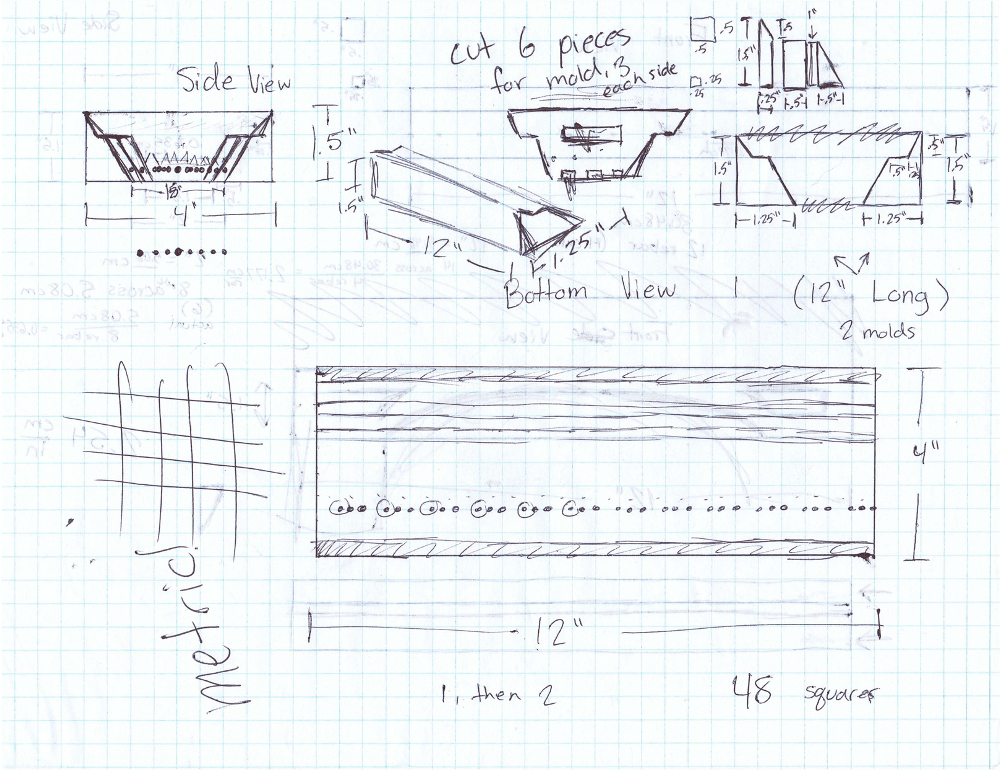

bridge that would hold considerable weight while remaining efficient. The bridge had to be 12” long, 4” wide, and

1.5” tall. Instead of rebar we used 2

welding wires twisted together. Once the

mold for the bridge was created, we would mix concrete, pour, then test the

bridges using the structural stress analyzer, after a couple days of drying.

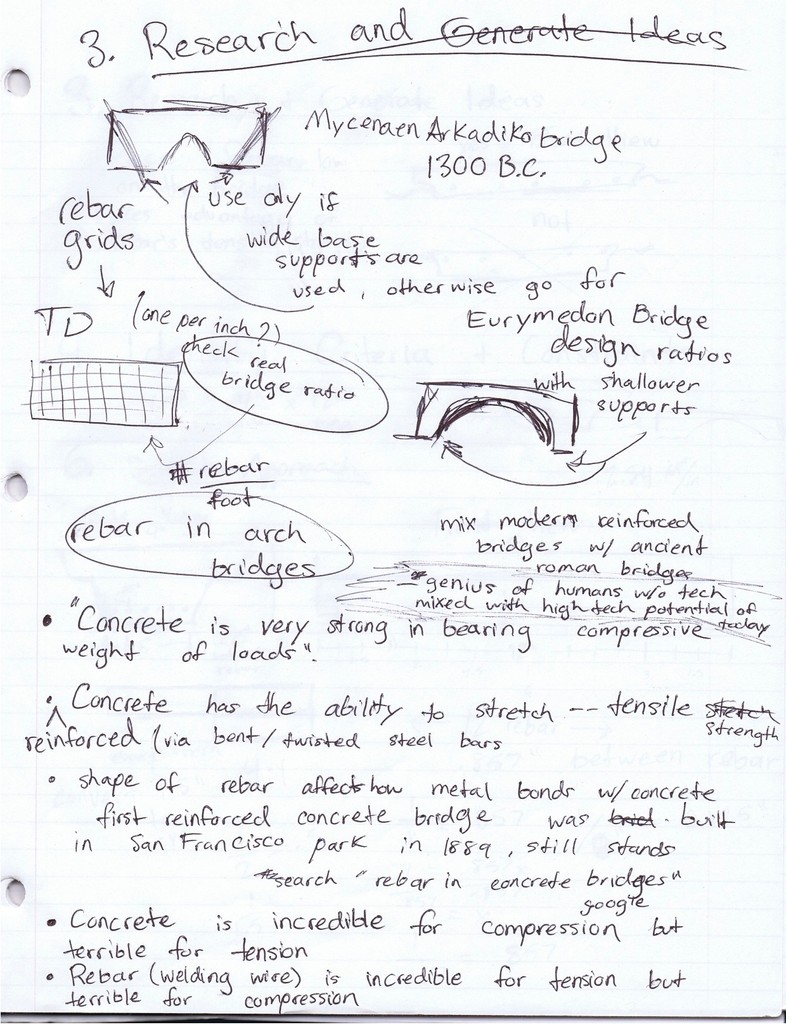

In creating our bridge,

Austin and I followed the 12-step engineering model;

beginning with brainstorming. We threw a

bunch of ideas and sketches down onto paper, and then we researched real

reinforced concrete bridges. This

allowed us to make a confident choice of which brainstorm to pursue bringing to

life. We refined our design and noted the

measurements. Then Austin assembled the

wooden box our bridge would dry in while I formed our foam molds.

Our bridge unfortunately broke while we were

removing it from the mold, as did many other groups’ bridges because we were

using expired concrete. We never got to

test the strength of our bridge.